Fabricating Aluminium Windows and Doors: A Step-by-Step Guide

Aluminum windows and doors combine durability, efficiency, and aesthetic appeal, making them a popular choice for residential and commercial properties. The fabrication process, however, involves detailed steps to ensure a perfect fit and high performance. At TSL Industries, we follow a comprehensive approach to creating aluminum windows and doors that meet the highest quality and functionality standards. To achieve this, we meticulously manage each phase of the process. In addition, we implement rigorous quality control measures throughout. Here’s an in-depth look at how we ensure excellence from start to finish.

1. Design and Planning

Customer Consultation: We start by understanding your specific needs, preferences, and the architectural style of your building. This ensures that every detail aligns with your vision.

Measurements: Accurate measurements of the window or door opening are crucial. We take precise measurements to ensure a flawless fit.

Design Development: Based on your requirements and the measurements, we create a detailed design. This includes the size, shape, style, and features of the window or door to ensure it meets your expectations.

2. Material Selection and Preparation

Aluminum Profiles: We select high-quality aluminum profiles, often extruded to specific shapes and sizes to ensure strength and durability.

Thermal Breaks: To enhance energy efficiency, we incorporate thermal breaks into the profiles. These breaks prevent heat transfer, improving insulation.

Hardware: We choose the appropriate hardware, including hinges, locks, and handles, to ensure smooth operation and security.

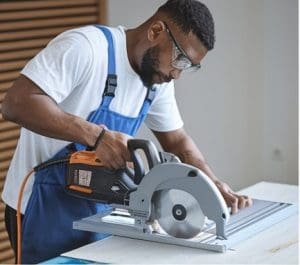

3. Cutting and Assembly

Cutting: Using specialized cutting equipment, we cut the aluminum profiles to precise lengths.

Joining: We join the cut profiles using methods such as welding, mechanical fasteners, or adhesive bonding to create a robust frame.

Frame Assembly: We assemble the main frame of the window or door, ensuring proper alignment and squareness.

4. Glazing

Glass Selection: We determine the type of glass—single-pane, double-pane, or triple-pane—based on your needs and local building codes.

Glass Cutting: We cut the glass to the exact size required for the window or door.

Glazing: We insert the cut glass into the frame and secure it using glazing beads or other appropriate methods to ensure a secure fit.

5. Hardware Installation

Hinges and Locks: We install hinges and locks on the frame and sash, ensuring they operate smoothly and securely.

Handles and Other Hardware: Additional hardware, such as handles, latches, and weatherstripping, is installed as needed to complete the functionality.

6. Finishing and Coating

Surface Preparation: We prepare the surface of the aluminum by cleaning and sanding to remove any imperfections.

Coating: A protective coating, such as powder coating or anodizing, is applied to enhance durability, appearance, and corrosion resistance.

7. Quality Control

Inspection: We inspect the finished window or door to ensure it meets all quality standards and specifications.

Testing: Functional tests are conducted to verify the operation of the hardware and the overall performance of the window or door.

8. Packaging and Shipping

Packaging: The finished product is carefully packaged to protect it during transportation.

Shipping: We ship the window or door to your location or to the installation site with care.

9. Installation

Preparation: We prepare the installation site, including removing any existing windows or doors.

Installation: The window or door is installed in the opening, ensuring proper alignment and security.

Finishing Touches: Additionally, we complete any necessary finishing touches, such as caulking or sealing, in order to ensure a perfect final result.

Additional Factors to Consider

Customization Options

- Shapes and Sizes: We can easily shape and customize aluminum to meet specific architectural requirements, including non-standard sizes and shapes. In addition, we offer a wide range of styles, from traditional to contemporary, to match your design preferences. Moreover, we can incorporate additional features, such as built-in blinds, security enhancements, and energy-efficient glazing options.

Energy Efficiency

- Thermal Breaks: Thermal breaks are crucial in preventing heat transfer through the aluminum frame.

- Glazing Options: Low-E coatings, argon gas fills, and triple-pane glazing can significantly improve energy efficiency.

Security

- Reinforced Frames: Moreover, frames can be reinforced with thicker aluminum or additional structural elements to enhance security. Additionally, we use high-quality locks, hinges, and other hardware to provide added protection against forced entry.

Maintenance

- Low-Maintenance Material: Aluminum is durable and low-maintenance, requiring minimal upkeep. Additionally, regular inspections and timely repairs of the coating help maintain the appearance and performance of the windows and doors.

Accessibility

- Accessibility Features: We design aluminum windows and doors to meet accessibility requirements, including wider openings and easy-to-operate hardware.

Environmental Impact

- Recyclability: Aluminum is highly recyclable, making it an environmentally friendly choice. Furthermore, we are committed to sustainable practices, including energy-efficient production processes and responsible sourcing of materials

By considering these additional factors, you can select aluminum windows and doors that not only fulfill your functional and aesthetic needs but also contribute to energy efficiency, security, and sustainability. At TSL Industries, we are dedicated to providing you with high-quality aluminum solutions tailored to your requirements.